Aluminum Plate Panel Systems

SL-2000P

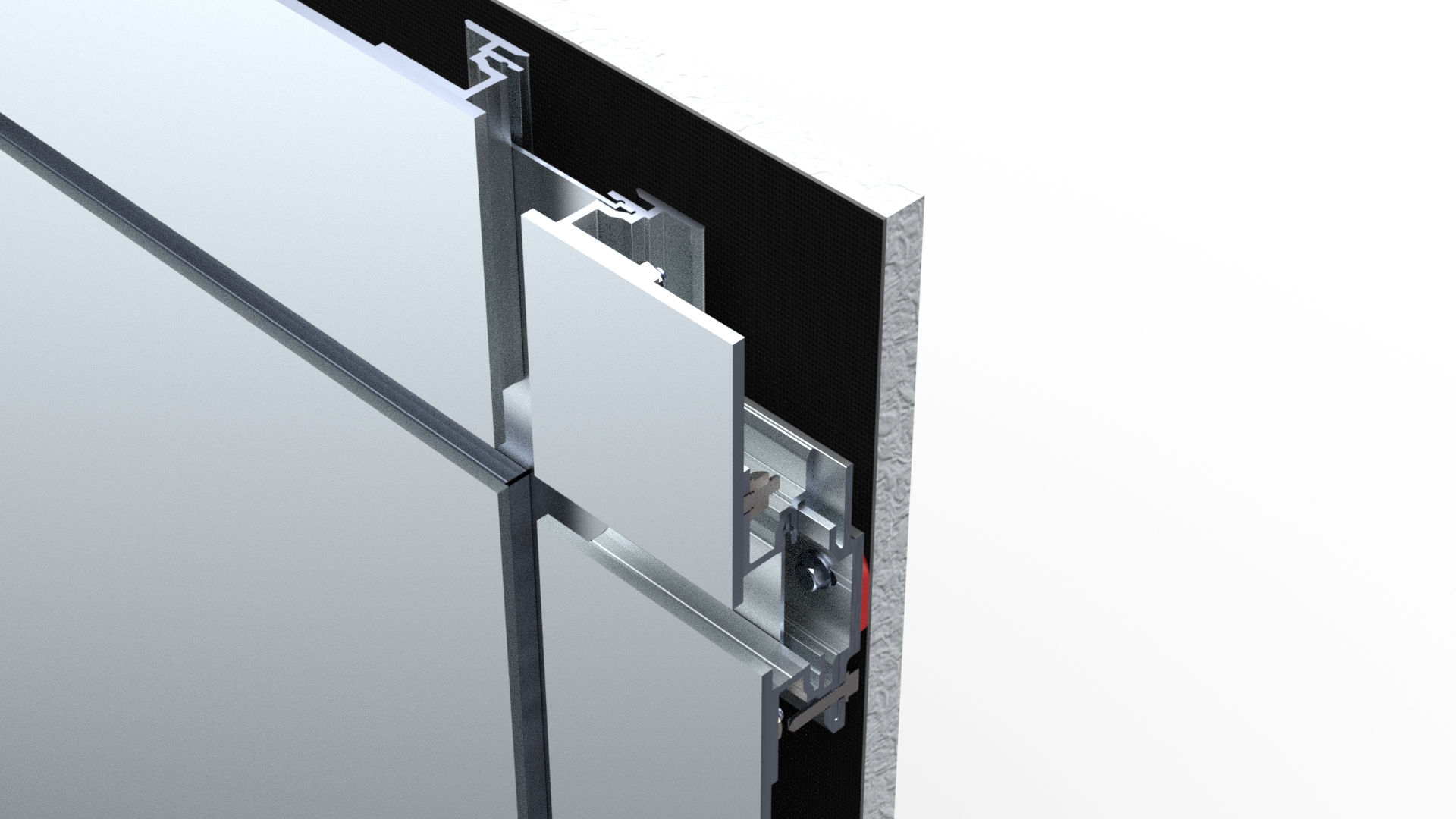

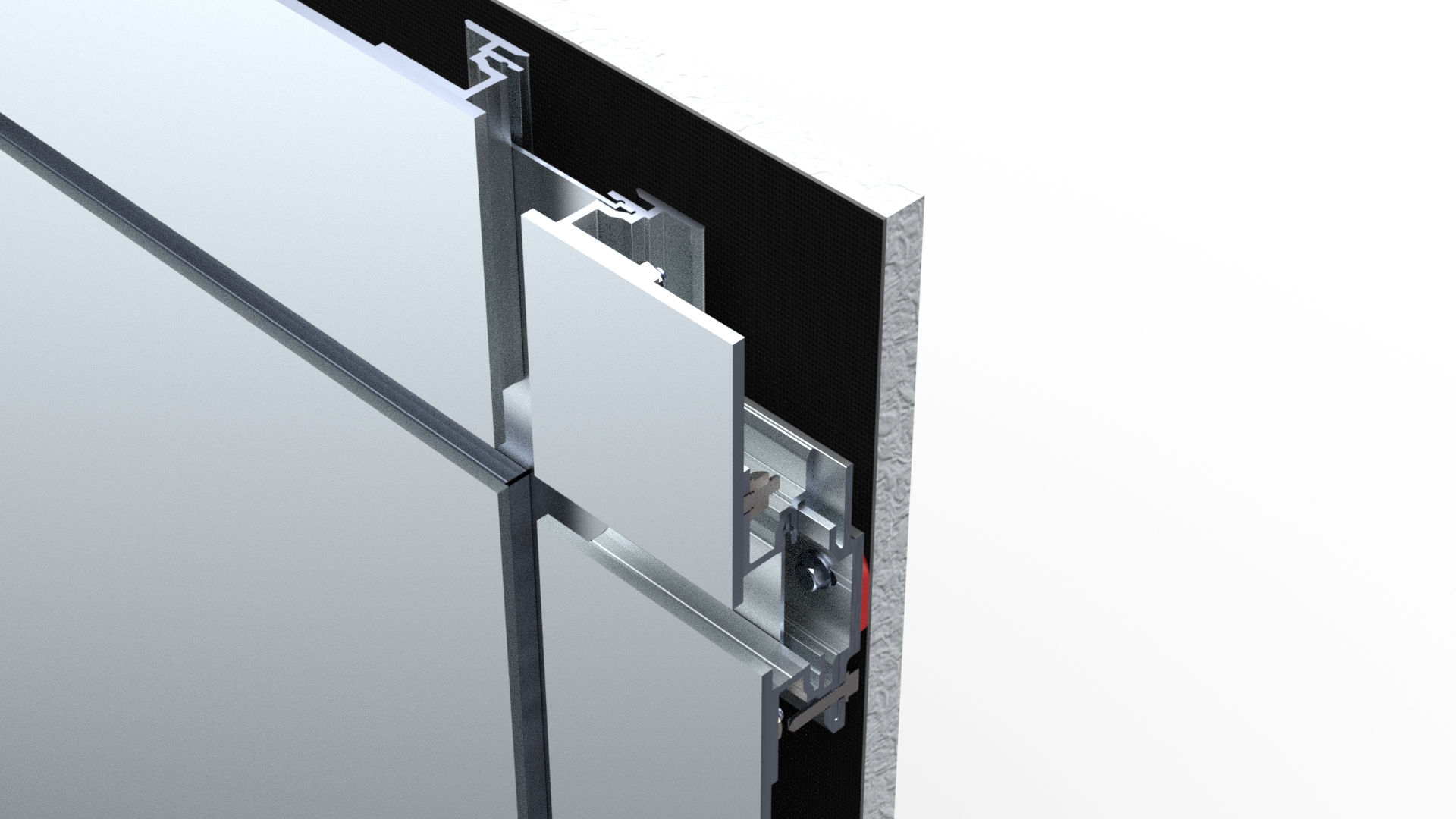

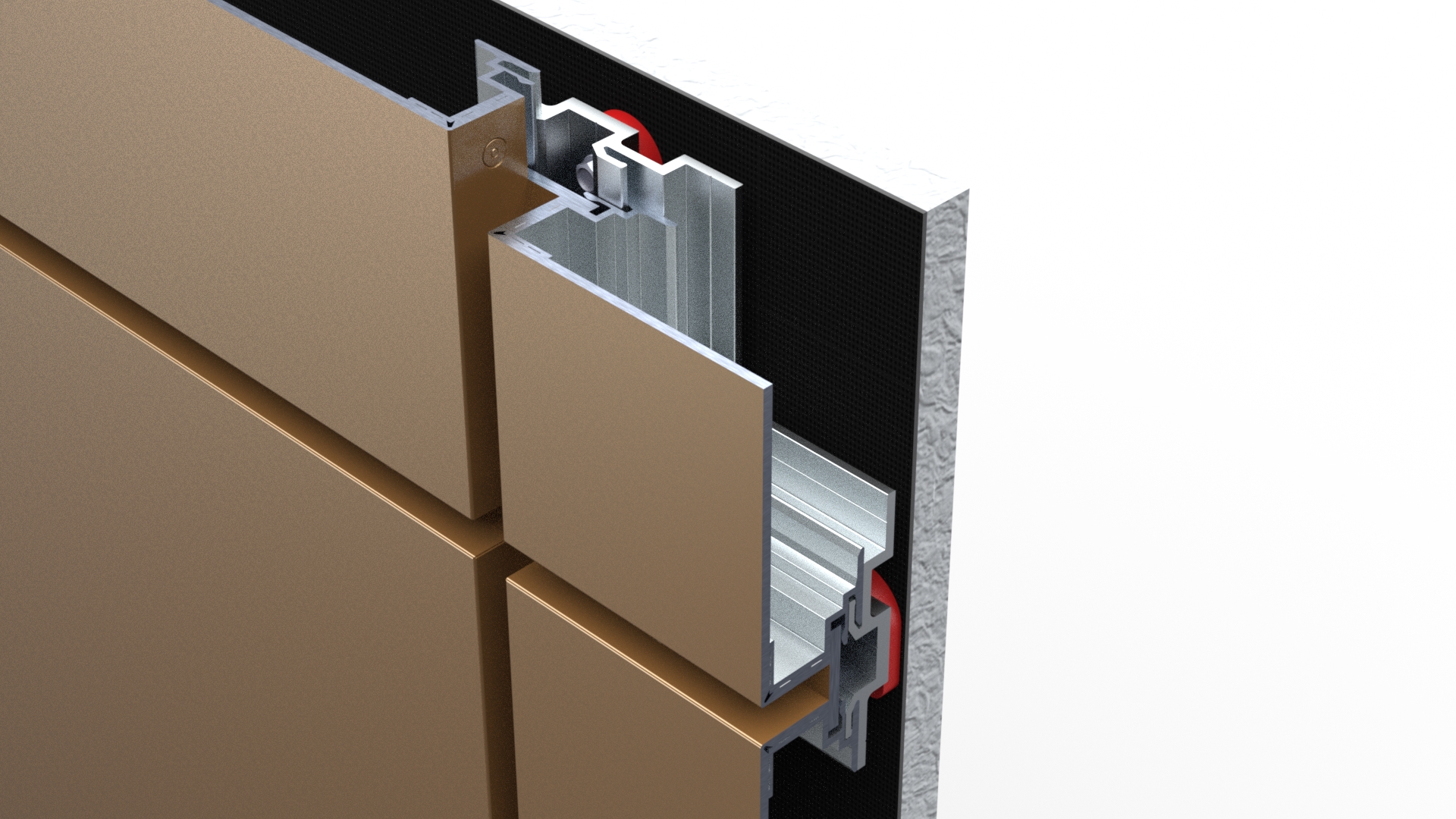

Dry Joint Pressure Equalized Rainscreen (PER) SystemThe SL-2000P system is another low-maintenance PER system with numerous design and fabrication options. Similar to the SL-1000P, this system incorporates solid metal materials at the panel joints. The wall attachment, air/vapour barrier seals and joint treatment are to the Sobotec SL-2000 standards, yet uses solid aluminum plate material. The joint filler for this system can also vary in both color and joint size. This systems meets the same testing criteria of the American Architectural Manufacturers Association (AAMA) 508 standard for PER systems. The SL-2000P system can also be used with natural metals such as zinc, copper and stainless steel. Yet aluminum plate is most often used when requiring a painted surface.

- Pressure Equalized Rainscreen System

- Ventilated cavity allows wall to breathe

- Joint filler allows for variable color and reveal size

- Low-maintenance, flexible panel design

- Concealed air barrier membrane provides improved weather resistance

System Characteristics & Testing

Material:

1/8” (~3mm) Aluminum Plate

Dry

Testing:

Wall Design:

Pressure Equalized Rainscreen System

SL-5000P

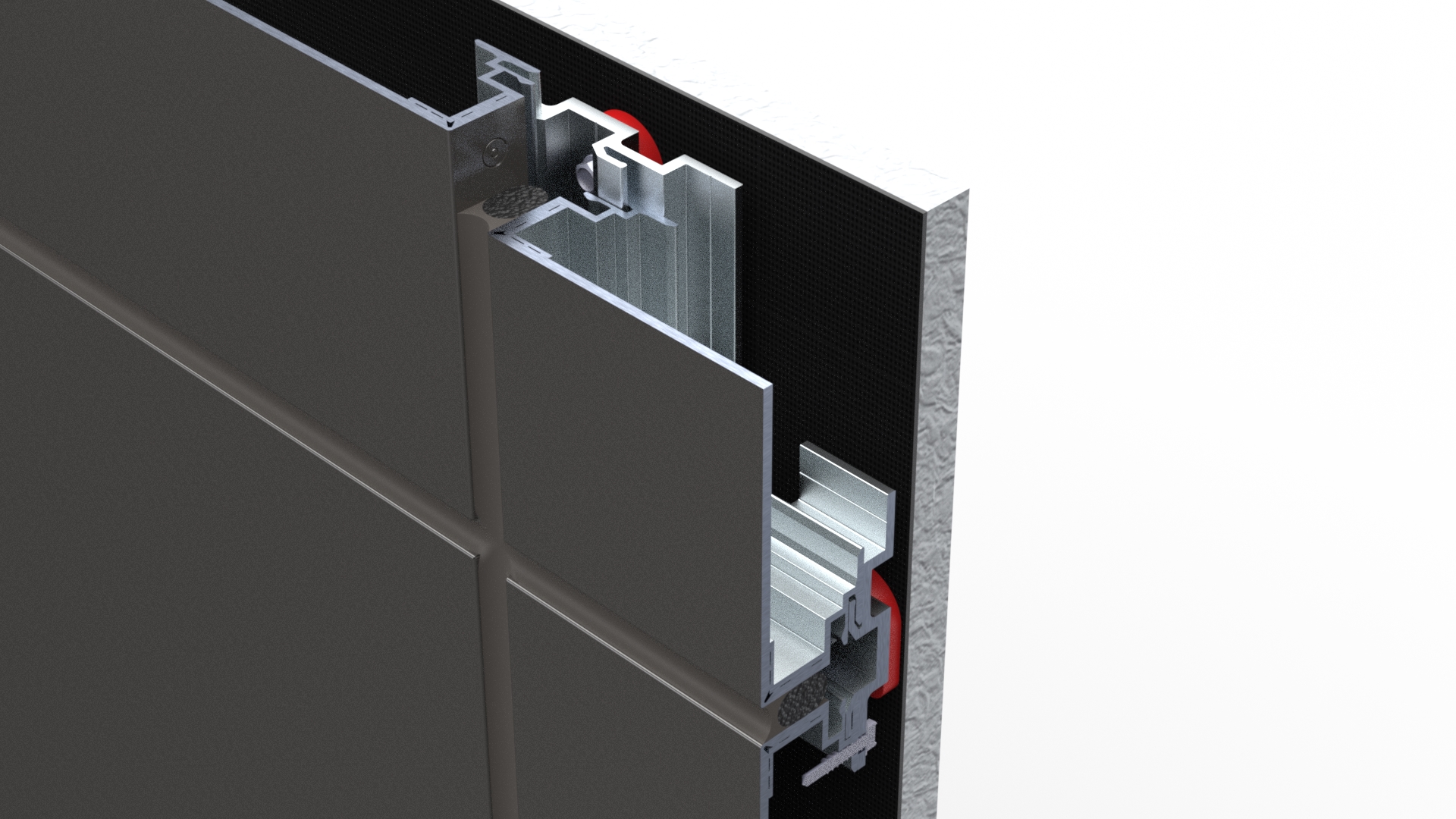

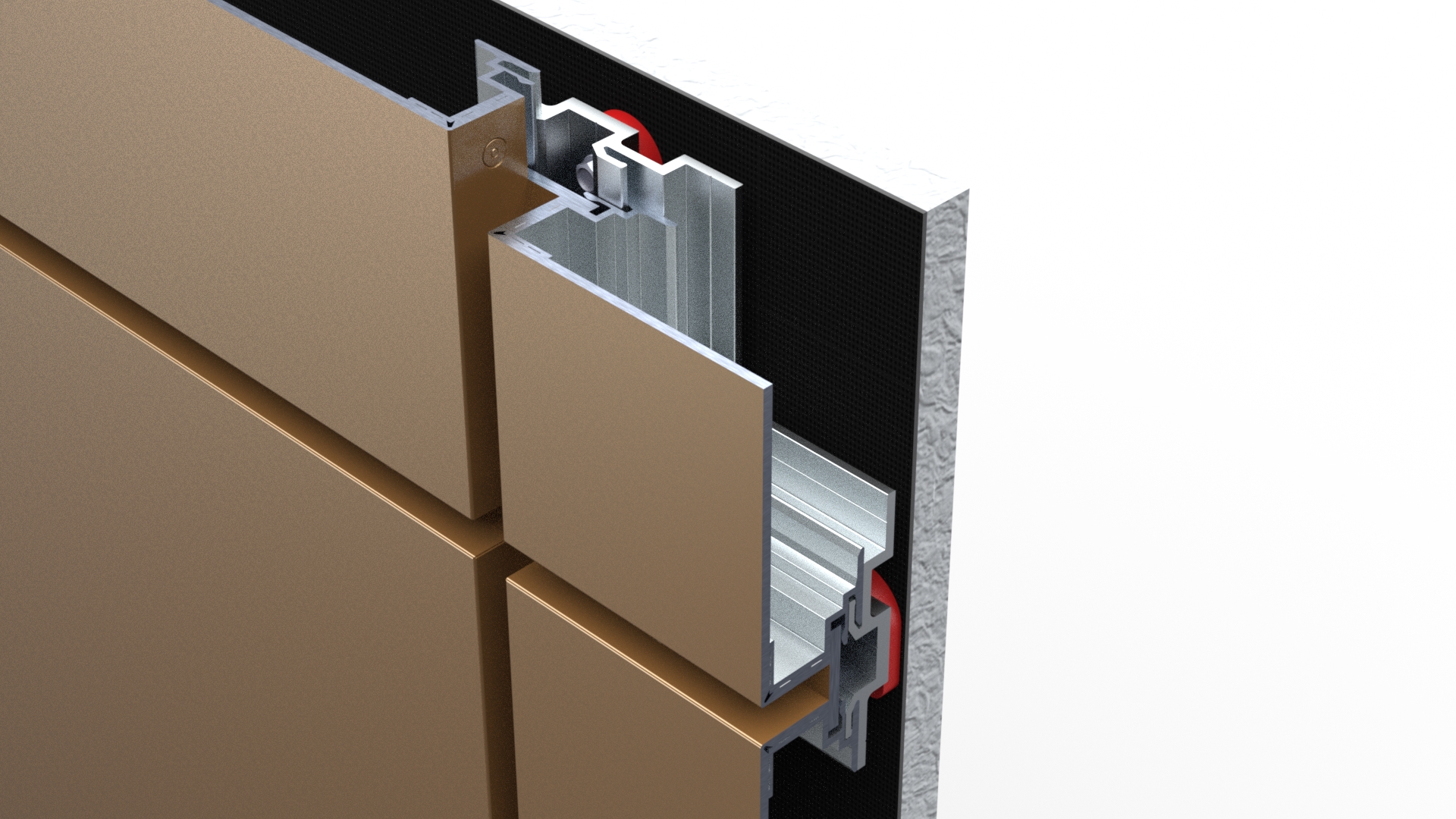

Dry Joint Pressure Equalized Rainscreen (PER) SystemThis heavy gauge, solid plate PER System is used on monumental projects where a floating, exposed panel edge appearance is desired. The attachment system is custom engineered using welded studs to minimize heat transfer to the face of the panel.

The panel joint is typically recessed and finished in a dark color to create a shadow effect. Alternatively, the joint size, finish and configuration can be modified to suit project specifications. The SL-5000 system has been fully tested to satisfy all code requirements in addition to full-scale testing of individual panels to establish stud behavior under various loads.

- Pressure Equalized Rainscreen System

- Floating appearance with an exposed painted panel edge

- Low-maintenance, flexible panel design

System Characteristics & Testing

Material:

3/4"

Testing:

Wall Design:

Pressure Equalized Rainscreen System